Manufacturing, Processing, & Fabrication Services That Keep You On Schedule

Fabrication services get your metals & supplies kitted and delivered ready for assembly, saving time and money.

Your Metals Delivered Ready for Assembly

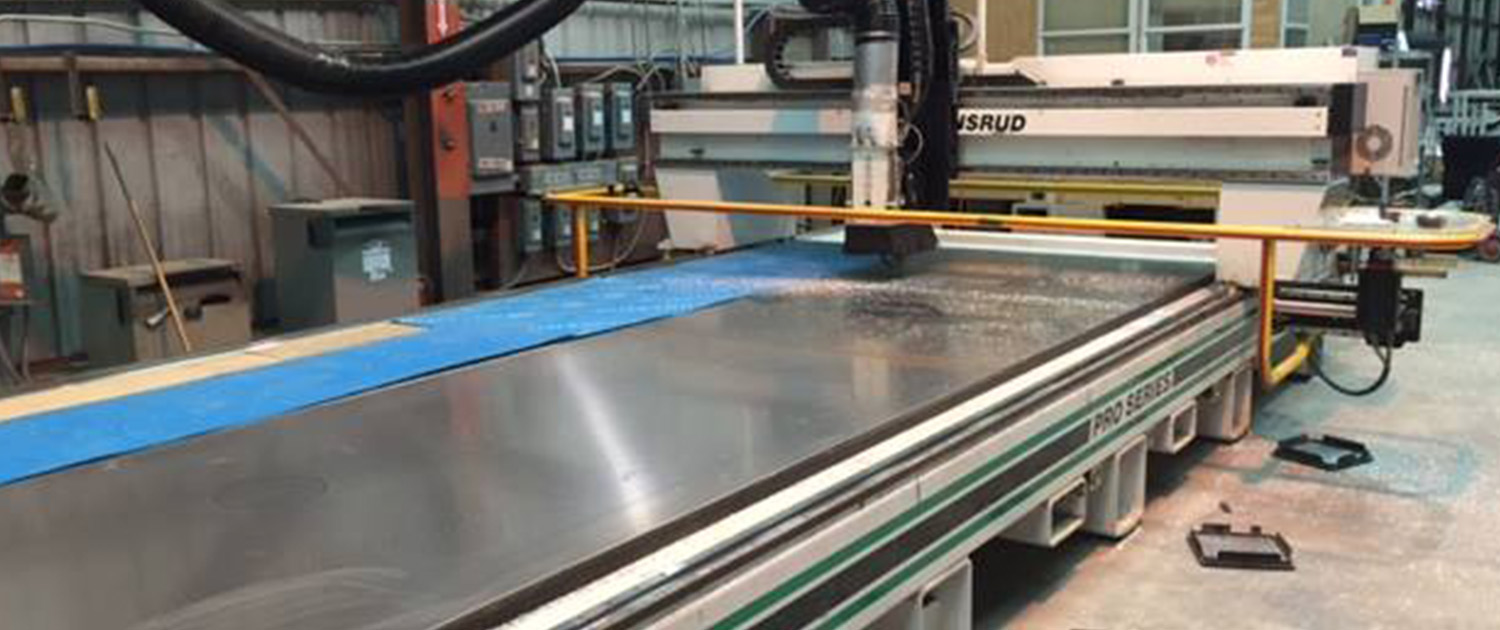

Bayou Metals offers value-added metals processing, such as precision router cutting with our (1) onsite 12’ x 68’ and (2) 8’ x 40’ CNC routers, cutting to length, plasma cutting, precision sawing, and shearing, and more, before distributing these products to manufacturers and other end-users.

In 2018, the owners formed a production company, Bayou Manufacturing Services, which extends the value-added services to include Friction Stir Welding and weld shop fabrication capabilities to our customers all on the same property.

Committed To Saving Our Customers Time & Money

CNC Routing

Up to 12′ X 68′Aluminum Routing

Bayou Metal Supply Offers High-Precision CNC Milling Services Bayou Metal Supply offers a wide range of metal processing services, including friction stir welding, shearing, and precision router cutting, to manufacturers and end users in Louisiana and throughout the Gulf Coast. Our extensive processing capabilities set us apart from other metal processing services. Our machine shop is equipped with three CNC routers.

Metal Bending

Up to 400 TON / 24′ Material Bending

Press brakes are used to bend metal. They eliminate the need to forge and hammer metal into desired shapes, which can be lengthy. A press brake applies force to push sheet metal into a U- or V-shaped dye. Different types of sheet metal bending include bottoming, air bending, coining, wiping, folding, rolling, and joggling.

Friction Stir Welding

Friction Stir Welding

FSSW is similar to traditional FSW but uses smaller tools. The process involves inserting tiny pins into pre-drilled holes, eliminating the need to form full-length runs along large components. FSSW is often used to weld aluminum sheets up to 6 mm thick. Automobile manufacturers utilize the process to join thin metal sheets together quickly and efficiently without affecting the quality of welds produced.

Plate Saw

5” thick x 24’wide

9” thick x 54” wide

In this process, sheet metal is pushed down over the edge of the die to form a bend. The press brake presses the metal plate until the metal bends over the die’s outer edge.

Shear

0.063” to 3/8” thick x 12ft wide

Sprawling over an area of 160,000 sq ft, our warehouse is stocked with a wide variety of materials. Our manufacturing facility is outfitted with state-of-the-art fabrication tools designed to cut, shear, and bend materials in custom shapes.

CNC Machining

Mill and Lathe

Modern machine shops are outfitted with advanced CNC machines that utilize cutting-edge technology to cut metals in custom shapes. Advanced CNC machines open a world of new possibilities, helping project managers meet unique project specifications.

MFG in USA

MFG in USA